Why High-Speed Bearings Matter for Powersports and Racing Engines

Despite their critical role, high-speed bearings are often not considered and underutilized, even though they can have a significant impact on engine performance and reliability.

Read on to find out more about high-performance racing engine bearings, which types are most commonly used in racing applications, and the benefits they can bring to your performance.

What are Racing Engine Bearings?

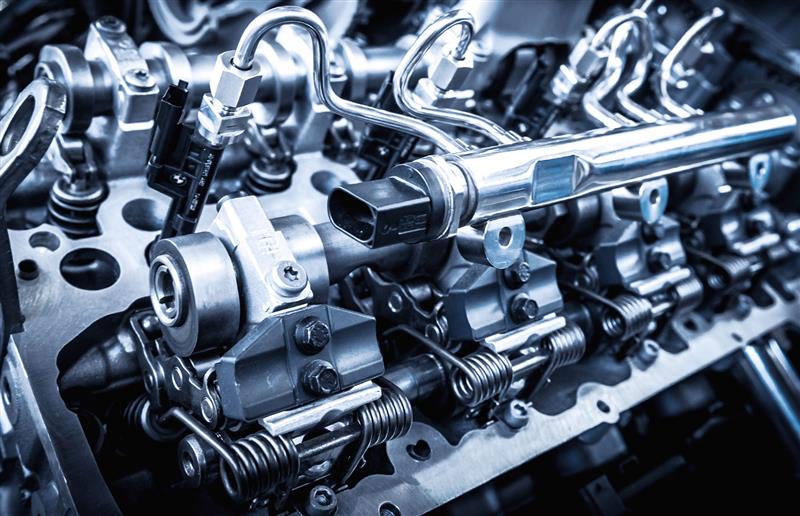

Racing engine bearings are precision-engineered components that minimize friction between moving parts within an engine. They are vital to a racing engine’s performance, as they help facilitate the smooth rotation at high RPMs, and withstand extreme stress and heat generated during high-speed operation.

Racing engine bearings are different from normal bearings because they are designed to endure the intense demands of competitive Motorsports and powersports applications. Using standard bearings on racing engines would result in premature wear, reduced efficiency, and potentially catastrophic engine failure under high loads.

Common Types of Racing Engine Bearings

Different types of bearings are tailored to meet the varying demands of high-speed racing engines. Here’s an overview of the most common high-performance bearings used in Motorsports.

Deep Groove Ball Bearings

Although a common type of ball bearing, Deep Groove Ball Bearings have standout features which make them popular in racing engines. Their ability to reduce friction significantly, and handle both radial and axial loads, makes them suitable for high-speed applications.

Roller Bearings

Roller Bearings are also extremely useful when installed in powersport and racing engines. Cylindrical Roller Bearings and Taper Roller Bearingsspecifically stand out because of their ability to withstand high loads and absorb shocks, which make them ideal for high-torque applications and heavy-duty racing conditions. You will typically find these bearings used in drag racing engines, off-road racing engines, and rally car engines, where extreme torque, frequent directional changes, and heavy impacts are common.

In addition to this, Needle Roller Bearings are used in racing engines as they are able to distribute loads over a larger surface area, meaning they reduce stress and wear. This contributes to longer bearing life and reliable performance even in extreme conditions.

Benefits of High-Performance Bearings for Powersports and Racing Engines

Using high-performance bearings for your powersports and racing engine comes with several benefits.

Durability

It is essential to prevent bearing or engine component failure during high-speed racing or off-road competitions, as this would ruin the chances of finishing or winning the race. High-performance racing engine bearings are built with components that are able to withstand extreme temperatures, high RPMs, and heavy loads, ensuring consistent performance during intense races.

Reduced Friction

These bearings are able to minimize metal-to-metal contact, which benefits racing performance because they reduce energy loss, prevent overheating, and allow for smoother, more efficient engine operation.

Increased Longevity

The advanced materials used in racing engine bearings mean they are able to resist wear and tear effectively throughout long-distance and duration races in harsh conditions. This reduces the need for frequent replacements and minimizes downtime.

Optimized Performance

High-performance racing engine bearings enable the engine to operate at peak efficiency, giving you a competitive advantage in motorsports and powersports.

Choosing the Right Bearings for Your Racing Engine

Selecting the appropriate bearings is crucial for ensuring your engine performs at its best. Here are key factors to consider

Material

The material of a bearing determines its strength, heat resistance, and wear properties. Bearings with ceramic and hybrid materials are ideal for high-performance engines due to their immense durability and low friction.

Load Capacity

Before choosing your racing engine bearings, you must understand the load-bearing requirements of your engine to ensure the bearings can handle the stresses without failing. For heavy-duty applications, such as off-road racing or drag racing, roller bearings are typically best.

Operating Speed

Choosing bearings with high-speed ratings is essential for racing engines, as the bearings must operate smoothly at extreme RPMs without overheating or causing vibrations. This can improve overall engine efficiency, reduce wear on internal components, and maintain stability during prolonged high-speed operation.

Maintaining High-Performance Racing Engine Bearings

You will want to keep your racing engine bearings in the best condition in order for them to deliver consistent and reliable optimal performance. To do this, you should consider the following.

- High-Quality Lubrication: Make sure you use premium lubricants specifically designed for high-performance applications, such as Shell Lubricants, which specialise in keeping high-speed bearings cool and efficient by reducing friction.

- Inspection: Racing engine bearings should be frequently checked for any signs of damage, contamination, or wear.

- Proper Installation: Without proper installation, you run the risk of your bearings being misaligned in your racing engines, which can result in premature bearing failure and reduced engine performance.

Explore Powersports and Racing Engine Bearings at Quality Bearings Online

As a leading bearing supplier across the globe, Quality Bearings Online have a comprehensive range of racing engine bearings designed to elevate your racing and powersport applications to the next level.

If you require high-performance racing engine bearings, or you wish to know more about which is the correct choice for you, please contact a member of our technical team who would be more than happy to help. Contact us

Contact Us

Recent Posts

-

Our Commitment to our US Customers

At Quality Bearings Online, our customers are at the heart of everything we do. Whether you're …16th Apr 2025 -

The Ultimate Guide to High-Performance CNC Machine Bearings

CNC machine bearings are mechanical components designed to minimize friction between moving par …3rd Apr 2025 -

Quality Bearings Online Awarded Independent Seal Of Excellence

For the fourth consecutive year, we’re thrilled to have won the Feefo Platinum Trusted Service …12th Mar 2025