The Difference Between Ball Bearings and Roller Bearings

It might be easy to assume that Ball Bearings and Roller Bearings are practically the same thing and, if needed, they can perform the same jobs. After all, they’re both bearings, both look similar from the outside, and they both spin! But that is where the similarities end. In this article, we will outline the distinctions, the different types, and how each can be used for the optimal efficiency of both the bearing and your machinery. Here at Quality Bearings Online, we offer a wide range of ball and Roller Bearings. You can browse our product selection via our website.

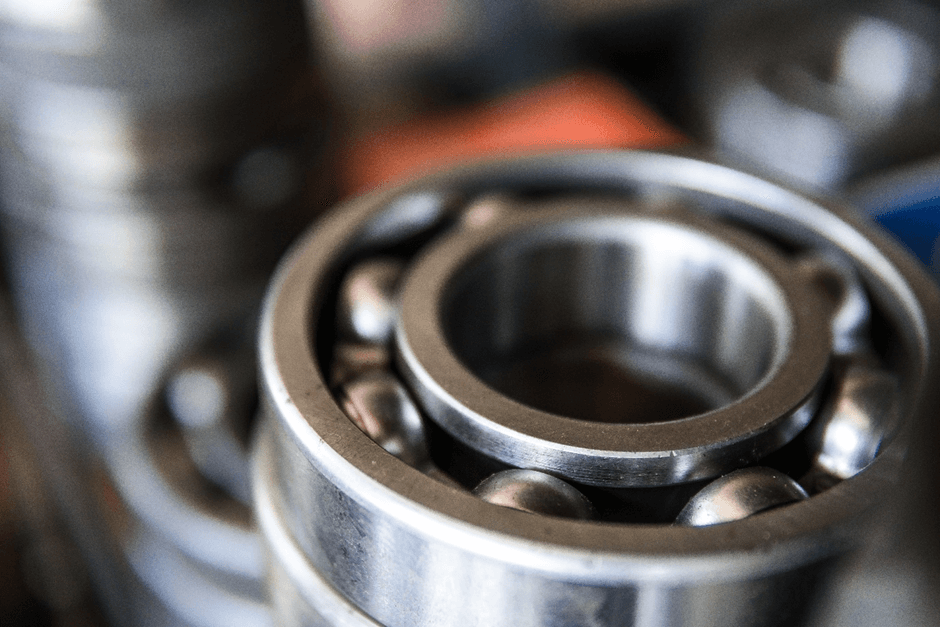

Understanding Ball Bearings

Bearings are used in everything we do, from cars, to planes to convey belts and microwaves. Ball Bearings are essential in many applications with wheels, such as automated vehicles, skateboards, and bicycles. Ball Bearings are used to reduce friction and wear on rotating parts while carrying and transmitting load. Using steel balls as the rolling element reduces the contact between the rolling element and the bearing raceway which minimises friction and improves the bearing’s speed. Lower raceway contact, while offering higher speed capability, means that the bearing can handle less load respectively than bearings using rollers as their rolling element.

Understanding Roller Bearings

Roller Bearings are often used in heavier equipment and machinery as compared to Ball Bearings. Like Ball Bearings, they are used to reduce friction and carry and transmit load. Roller Bearings are typically composed of the following components: the outer race, inner race, steel rollers as the rolling element, and the cage. They can contain single or multiple rows of rollers depending on the demand for radial load capacity as more rows significantly increases the bearing’s load capacity.

Key Difference Between Ball Bearings and Roller Bearings

There are many key differences between Ball Bearings and Roller Bearings which could be vital in deciding which is the correct type to use.

Load Handling Capabilities

A key difference between the two bearing types is their load handling capabilities. Roller Bearings are more often chosen for handling heavy radial loads whereas Ball Bearings are more commonly chosen for lighter loads. Ball Bearings have a smaller contact area and therefore have less capacity for high loads. Whereas Roller Bearings are designed to carry higher loads as they can distribute the load over a larger surface area.

Speed Capabilities

It is vital when choosing a bearing to consider the speed capacity, as the speed of machinery can massively affect the smoothness of the operation if the wrong bearing is implemented. Ball Bearings are often chosen for high-speed appliances as they have lower frictional resistance than Roller Bearings.Roller Bearings are most effective at lower speeds and heavier loads due to their larger contact area.

Applications

Another key difference between Ball Bearings and Roller Bearings is the applications in which they are used.Ball Bearings are commonly used in everyday applications, for example, washing machines, bicycles, dental equipment, air conditioners, electric fans, electric motors, and kitchen appliances. On the other hand, Roller Bearings are more likely to be used in heavy machinery, applications involving high pressure and continuous operation, such as printing presses, and automotive gearboxes.

Advantages of Ball Bearings

There are many advantages of using Ball Bearings. One of the key benefits when using a Ball Bearing is they are highly durable therefore, they don’t need replacing very often. In addition, because they are so durable they require minimal maintenance if mounted correctly. As previously mentioned, Ball Bearings can handle high rotational speeds, therefore they are suitable for high-speed machinery. A final advantage of Ball Bearings is their low friction, which results in minimal heat and noise generation during operation.

Advantages of Roller Bearings

There are many advantages to using Roller Bearings. They offer excellent load carrying capacity in a variety of configurations meaning there is always an appropriate option for any application, regardless of the space allowance. Roller Bearings are also often more structural rigid and hard-wearing than Ball Bearings of the same size and therefore they can be used in tougher environments and more demanding applications. Despite their increased raceway contact, Roller Bearings can still handle relatively high rotational speeds alongside heavy loads, and as such they are universally used in gearboxes, automotive or otherwise.

Types of Ball Bearings

Each type of Ball Bearing is unique with different characteristics. One type of Ball Bearing is Deep Groove Radial Ball Bearings . These bearings have deep grooves on the raceway of inner and outer rings which allows them to accommodate radial and axial loads in both directions. They play a crucial role in smooth and seamless operations in countless applications and are one of the simplest and most common bearing types.

Another type is Double Row Angular Contact Bearings . These bearings contain two rows of balls giving them a larger contact angle to the bearing axis than other types of bearings. This provides an increased radial and axial load capacity with a compact design.

Another type of Ball Bearing is Double Row Self Aligning Ball Bearings . These bearings are made to be used in a wide variety of applications. They are designed to accommodate misalignment and shaft deflection. There are many more types of Ball Bearings which you can view with information about each category on the Ball Bearings page of our website.

Types of Roller Bearings

Like Ball Bearings, there are many different types of Roller Bearings, all with different properties. One type is Spherical Roller Bearings which are ideal for operating equipment in challenging conditions thanks to their robust design and ability to accommodate misalignment. Our range of Spherical Roller Bearings includes various sizes, load capacities, and configurations to meet your specific needs. Another type of Roller Bearings is Cylindrical Roller Bearings . These consist of cylindrical rollers held by a cage and often between an inner and outer ring. They are designed to manage high radial loads and moderate axial loads while maintaining space efficiency accommodating high speeds. Taper Roller Bearings are available in single row, double row, and multi row configurations. By design, these bearings are well-suited to carry combined loads of simultaneously acting radial and axial loads. As such, Taper Roller Bearings are used in many vehicle wheels and axels. Needle Roller Bearings are similar to Cylindrical Roller Bearings in terms of capability, but they have a much small profile and cross-sectional height, meaning they can be used in much smaller spaces. At Quality Bearings Online, we offer a wide range of Taper Roller Bearings. For more information, please visit our Roller Bearings page.

Ball Bearings vs. Roller Bearings

In conclusion, Roller Bearings and Ball Bearings are very different and have opposing properties which means they better suit different purposes. Ball Bearings are better suited to lighter loads and faster rotational speeds, whereas Roller Bearings are better suited to heavier loads.

If you require Roller or Ball Bearings or you wish to know more about which is the correct choice for you, please contact a member of our technical team who would be more than happy to help. Contact us or email sales@qualitybearingsonline.com

Recent Posts

-

Heavy Machinery Bearings: Solutions for High-Load Applications

High-load applications can be put under a lot of pressure in harsh conditions for long periods of …16th Dec 2024 -

How Are Ball Bearings Made and What Are They Used For?

Ball bearings are essential components in a wide variety of machinery and they play a critical ro …21st Oct 2024 -

Avoid Downtime With SKF Maintenance Tools

In industries that rely on heavy machinery, unexpected downtime can be costly and disruptive. Avo …30th Sep 2024