Spindles In CNC Machines – Why Are They Important And What Bearings Do They Use?

How Does A CNC Spindle Work?

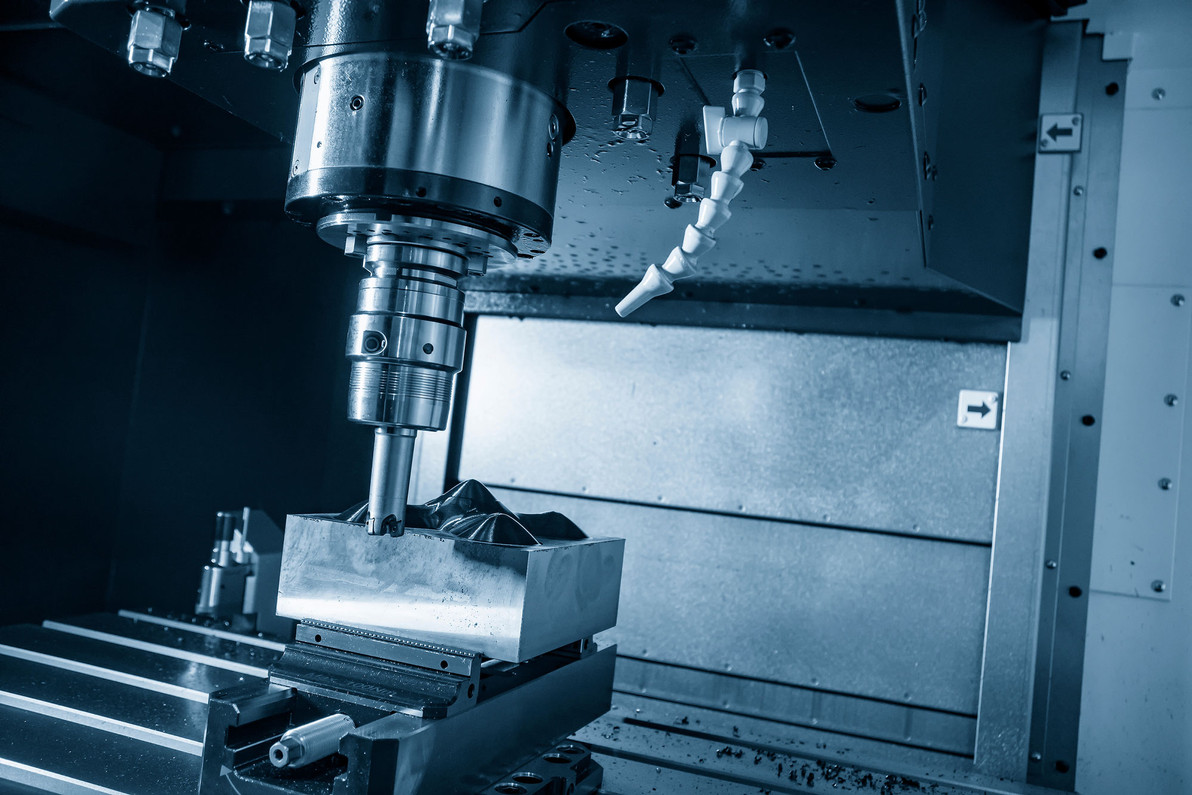

Spindles in CNC Machine Tools are the main rotating elements of the machine and often have a shaft at the centre. It’s the Spindle that rotates and facilitates the action of the machine, be that milling, laser cutting, or in lathes for example. Just as Spindles are the most crucial part of CNC Machines, Bearings are an essential part of a Spindle, if not the most essential part. Bearings enhance and direct Spindle movement, and the use of high-quality Bearings improves reliability and overall efficiency of the Spindle so they can perform faster and more accurately.

That’s why choosing the right Bearing is so fundamental in establishing how well your CNC Machine will perform. We’ll run through the types of Bearings found in CNC Machine Spindles to help you make the right decision for your application.

Bearings For CNC Machines

Precision Angular Contact Bearings - also known as Spindle Bearings - and are most often used in the main Spindle of CNC Machines and other Machine Tools. They can accommodate heavy axial loads at high speeds while maintaining running accuracy. All of which means that these bearings are ideally suited to applications in Spindles and CNC Machines, where precision and performance are paramount. SKF has the most extensive range of Super Precision Angular Contact Bearings. They are very high quality with multiple variations and are designed to meet specific application requirements.

Precision Cylindrical Roller Bearings used in Spindles are typically double-row and are used in combination with Precision Angular Contact Bearings (PAC Bearings). Where PAC Bearings contain balls with point contact on the inner and outer race, Cylindrical Roller Bearings contain rollers with linear contact on the inner and outer race. This linear contact means they have a high radial load carrying capacity and allow for higher speeds. These Bearings are useful in high-speed applications and are used to support radial loads and axial loads in one direction, enhancing motion and reducing friction in the Spindle.

Taper Roller Bearings are similar to Cylindrical Roller Bearings as they also use rollers instead of balls and benefit from the linear contact they afford. They too can support heavy loads in heavy-duty Machine Tool applications, along with high rigidity. Their composition provides the additional benefit of a conical design which can reduce torque and heat, while ensuring speed and accuracy.

Choosing the right Bearings can seem like an impossible task at times. If you are unsure which CNC Spindle Bearing is the most suitable for your machinery, our knowledgeable and experienced team are available to help discuss your needs and find that perfect solution. Contact Us

Here at Quality Bearings Online, we only stock original manufactured products from world renown brands like SKF, NSK, FAG, and Timken. Check out our extensive range of quality products needed for your applications.

Recent Posts

-

Quality Bearings Online Awarded Independent Seal Of Excellence

For the fourth consecutive year, we’re thrilled to have won the Feefo Platinum Trusted Service …12th Mar 2025 -

How to enhance machinery performance with Deep Groove Ball bearings

Deep Groove Ball bearings are used in a wide variety of machinery. These components are extremely im …10th Mar 2025 -

8 Benefits of Using Induction Heaters for Bearing Mounting

Bearing mounting is a critical step in many industrial and engineering applications, so ensuring pro …24th Feb 2025